Sr. Transportation Safety Editor — J. J. Keller & Associates, Inc.

Don't Let Supply-Chain Disruptions Derail Your Maintenance Program

There's a perfect storm of problems battering the truck and bus industry today. Learn how vehicle inspections and preventive maintenance help keep your freight moving.

Published On: 08/19/2022

Written by:

Daren Hansen

When it comes to vehicle maintenance, there’s a perfect storm of problems battering the truck and bus industry today:

- Skyrocketing costs for equipment, labor, and fuel;

- A tight supply of both new and used equipment and parts;

- Long service delays combined with a loss of qualified technicians; and

- General economic uncertainty.

None of these problems are clearing away soon. Maintaining your fleet in these stormy seas will require the right tools and the right preparation.

It Starts with Your Drivers

Pre- and post-trip inspections are always important, but they become vital as equipment ages. These daily inspections must be thorough, must be documented, and must be acted upon.

To ensure your daily inspection process runs smoothly and efficiently — and results in safe vehicles on the road — you need the right tools. Electronic DVIRs (eDVIRs) support all of these goals. An effective eDVIR system can:

- Ensure ongoing DOT compliance;

- Help organize, analyze, and track volumes of inspection data (without paper);

- Route the right information to the right people at the right time, so defects can be repaired and vehicles can remain in operation; and

- Help you spot trends and prioritize maintenance as your fleet ages.

Repair vs. Maintenance

As you think about what you need to maintain your changing fleet, consider the difference between repairing your vehicles versus maintaining them.

What’s the difference? Maintenance is a planned activity, based on your fleet’s preventive maintenance (PM) program. Repairs are what you need to do when a vehicle was not properly maintained. One is proactive, the other reactive.

Repairs — often required unexpectedly, on the road — will eat away at your bottom line, costing several times more than routine maintenance otherwise would have.

Older units are more prone to breaking down and needing repair, so careful inspections and preventive maintenance are key to keeping them on the road.

Choose the Right System

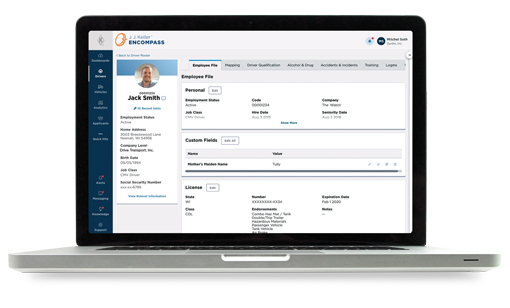

A fleet maintenance program is only as good as the system used to manage it. As with DVIRs, an electronic system can boost your chance of success. An effective fleet management system, like the J. J. Keller Encompass® Fleet Management System, can help you stay on top of preventive maintenance, track all maintenance costs, document and track all required inspections and repairs, maintain your parts inventory, and keep your fleet humming.

These are trying times for everyone, but without a comprehensive and organized inspection and maintenance program, you could end up with a fleet of unreliable and dangerous vehicles. The consequences could be steep.

With the right tools, an effective (and proactive) inspection and maintenance program won’t solve the supply-chain crisis, but it can help you lower costs, keep the highways safe, keep your freight moving, and make a tough economy a little easier to manage.

You may also enjoy the following articles:

Sign up for our newsletter!

We'll help you stay on top of regulations, best practices, and fleet industry news. Sign up to receive a monthly email notification with links to our most recent blog articles, free resources, and event invites.