Industry Business Advisor — J. J. Keller & Associates, Inc.

2022 CVSA Roadcheck Results — Wheel End Inspection Tips & Guidance

Each year, thousands of vehicle inspections are conducted during CVSA Roadcheck. Here are the results from the 2022 Roadcheck event.

Published On: 09/27/2022

Written by:

Rick Malchow

Each year during the CVSA (Commercial Vehicle Safety Alliance) Roadcheck event, tens of thousands of inspections are conducted. This year, Roadcheck occurred from May 17th through May 19th.

2022 Roadcheck Results

During the May Roadcheck event, CVSA inspectors performed 58,287 inspections in Canada, Mexico, and the United States placing 12,456 vehicles and 3,714 drivers out of service (OOS). When a vehicle or driver is placed OOS, the duration is for a specified time, or the identified violation is corrected.

Some notable overall North American results:

- Vehicle out-of-service rate was 22.8 percent (2021 out-of-service rate was 16.5%)

- Driver out-of-service rate was 6.4 percent (2021 out-of-service rate was 5.3%)

- False logs made up 45% of the driver out-of-service violations in the United States

- “Wrong license class” violations made up almost 35%

- In Canada, the top driver violation was hours of service, which was the primary reason for out-of-service driver violations at 76.3%.

- Inspectors in Mexico did not conduct driver inspections.

The event focused on wheel ends.

The wheel ends include the tires, wheels, rims, and hubs on a commercial motor vehicle. The failure of any of these components could lead to a crash, and violations are common, so it is no surprise that the CVSA paid particular attention to wheel ends during this year's three-day inspection blitz.

During Roadcheck, vehicle inspection officers checked various conditions around the wheel ends and placed vehicles out of service when necessary.

Do Not Let Your Guard Down

After a special enforcement event, drivers, carriers, and maintenance teams can be tempted to let their guard down and move on to the next hot issue of the day. Due to the critical nature of the wheel ends, this must be resisted. Fleet managers need to review their roadside data and inspections and look for trends. Read the Five Fleet Manager Tips for Vehicle Inspections blog.

Drivers need to look for the following wheel-end issues every day:

- Leaks in the tire, valve stem, or inner wheel seal

- Proper tire inflation

- Cuts or bulges on a tire

- Regrooved tires on a steering axle

- Tread wear

- Improper repair to sidewall (e.g., tire plugs)

- Exposed fabric or cord

- Contact between tires or with any part of the vehicle

- Tires that are marked as being excluded from a steering axle

- Debris between tires

- Cracked, bent, or broken rims

- Loose, broken, damaged, or missing lug nuts

- Elongated stud holes

- Cracked or unseated locking rings, studs, or clamps

- Cracks across spokes or slippage around the clamp

- Hub lubricant leaks

- Missing hub caps or plugs

Drivers must also be aware of wheel-end issues out on the road. They must use all their senses to detect any unusual conditions related to the wheel ends (or any other components), such as:

- Smoke from a wheel end

- Overly hot hubcaps

- Wheel noise, vibration, or wobble

- Decreased braking power/increased stopping distance

- Abnormal pulling when braking

- Wheel lock-up or skidding.

With many fleets extending vehicle trade-in cycles and holding on to vehicles longer, due to availability and cost, more items reach their life cycle with the initial owner or lessee of the vehicle. Therefore, a review of what is covered in each preventive maintenance schedule may be required.

Litigation Considerations

There are incentives for ensuring the vehicle's components are in good and safe operational condition. A familiar “big stick” consequence includes roadside inspection violations when the components are not in good working order.

However, wheel end defects found in a post-accident investigation and defects that existed before the accident can be used against carriers and drivers in a courtroom. A plaintiff’s attorney may argue that the defect was a significant contributor to the accident and is evidence that the driver and carrier had “complete and utter disregard" for the vehicle's safe operation and the motoring public's safety.

Staying on Top of Vehicle Inspections

- Drivers should be checking their wheel ends during every pre- and post-trip inspection. In fact, Sections 392.7 and 396.11 include the tires, wheels, and rims among the items to be included in every vehicle inspection.

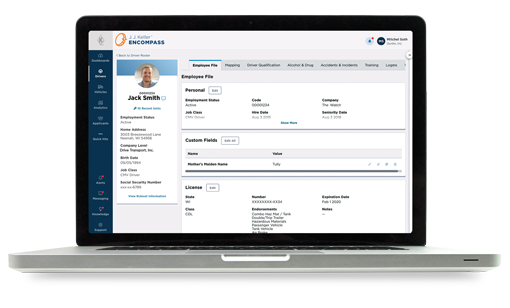

- Automate your processes. Many fleets have realized better inspection results using electronic inspection tools – such as electronic DVIRs (eDVIRs). The automation that comes with electronic vehicle inspection and maintenance solutions, like J. J. Keller® Encompass, can prove invaluable in reducing your fleet’s manual effort and improving operational effectiveness.

- Incentivize creatively towards better vehicle maintenance. Due to the driver shortage, most recruitment dollars are budgeted toward sign-on bonuses. Instead, consider incentivizing thorough driver vehicle inspections, such as finding inspection bonus tags, clean roadside inspection rewards, etc. These programs improve roadside inspection results, decrease over-the-road repairs, increase vehicle life spans, and make equipment safer.

A proactive approach to vehicle inspections that includes fleet maintenance automation will help you better manage your operation’s safety, costs, and vehicle longevity.

Roadside Inspection Compliance

Using a fleet management system, like J. J. Keller® Encompass, allows you to track all your roadside inspections and CSA data, plus driver and vehicle records. Alerts for expired credentials, tags, and permits help you eliminate unnecessary violations. Call 855.693.5338 to talk with a compliance specialist today to learn more about the Encompass 60-day free trial.

You may also enjoy the following articles:

Sign up for our newsletter!

We'll help you stay on top of regulations, best practices, and fleet industry news. Sign up to receive a monthly email notification with links to our most recent blog articles, free resources, and event invites.