Sr. Industry Business Advisor — J. J. Keller & Associates, Inc.

Three DOT-Required Driver Vehicle Inspections

All inspections strive to keep the vehicle in good condition and operating safely.

Published On: 06/01/2024

Written by:

Tom Bray

A critical component of an effective maintenance program includes a driver’s daily inspections of the vehicle, including a pre-trip inspection (§392.7, §392.8, §392.9, and §396.13), en-route inspection (§392.9 and §397.17), and post-trip inspection (§396.11). While they each have their own unique requirements, all the inspections have the same goal — to keep the vehicle in good condition and operating safely.

Pre-Trip Inspections

Under §392.7 of the Federal Motor Carrier Safety Regulations (FMCSRs), the driver must be satisfied that the vehicle is in “good working order” before operating it. The regulations provide a short list of 11 items that must be checked. The regulations do not require that the pre-trip be documented or reported to the carrier. If the driver finds something wrong with the vehicle, he or she is to get it fixed before operating it. If something is repaired, a document would be created to capture the type of maintenance for record retention.

En-Route Inspections

The regulations require certain drivers to do en-route inspections to check cargo securement and their tires. Cargo securement inspections are required within the first 50 miles after loading, and then every 3 hours, 150 miles or at a duty change, whichever comes first. However, if the driver is transporting cargo that is sealed in the cargo area or loaded in such a way that checking securement is not possible, the driver is not required to check the cargo securement.

Drivers transporting hazardous materials must check their tires before beginning the trip, any time the vehicle is parked, and then at the end of the trip. If the driver discovers a low or flat tire, the driver can proceed to the nearest place to have it repaired. However, if the tire has overheated, the driver may not operate the vehicle again until the tire has been repaired.

All drivers should be trained — and expected — to do a quick walkaround inspection of the vehicle every time it is parked. This simple inspection can prevent a lot of problems by spotting defects that have developed since the driver’s pre-trip, such as a flat tire, before they become catastrophic and lead to a breakdown, an out-of-service order, or an accident. This is done at a walking pace and involves:

- Having the running lights and 4-way flashers on

- Checking the tires, lights, and hubs for heat or leaks

- Cargo securement

- General securement check (nothing dangling loose)

Post-Trip Inspections

At the end of the workday, the driver may need to report the condition of the vehicle to the company. This inspection, required by §396.11, is referred to as the post-trip inspection even though that term is not used in the regulations. This is done by the driver submitting a daily vehicle inspection report, or DVIR.

In the case of a passenger-carrying driver, the driver must file a DVIR at the end of each workday. However, property-carrying drivers have an exception that allows them to submit a DVIR only if there is a defect on the vehicle, unless the carrier requires the driver to file one daily, which a lot of carriers do.

The key here is that if the driver must, or may have to, report on the condition of the vehicle to the company, the driver must do an inspection. A post-trip inspection involves checking roughly the same items that are checked on pre-trip, with the exception of fluids and hot items. For example, the driver shouldn’t physically touch the exhaust pipe or any of the hot engine components during a post-trip.

Bottom Line

The best practice is for the driver to use a disciplined step-by-step approach to inspect the vehicle. This makes it easier for the driver to remember what to check when, and greatly reduces the odds that the driver will miss something. As well as teaching the steps, you need to train the drivers on what must be checked in each step, and what is acceptable and not acceptable when it comes to the vehicle’s components, as far as your company and the regulations are concerned. Ensuring driver’s perform required inspections goes a long way to reducing violations, protecting your bottom line, and keeping your freight moving.

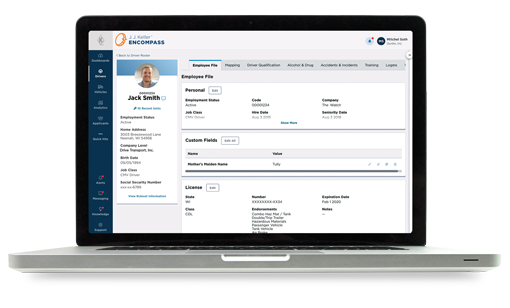

Improve Vehicle Inspections with the Encompass® DVIR App

The J. J. Keller® Encompass® eDVIR App offers a standalone solution for managing vehicle maintenance & upkeep, including options to customize vehicle inspection criteria according to a fleet's specific vehicle type. Included for all Encompass subscribers, the app requires no ELD hardware and is ideal for mixed fleets and non-regulated drivers. Learn more.

You may also enjoy the following articles:

Sign up for our newsletter!

We'll help you stay on top of regulations, best practices, and fleet industry news. Sign up to receive a monthly email notification with links to our most recent blog articles, free resources, and event invites.